Category Definitions

The MACIES data collection encompasses all major instrumentation categories across the Process Industries. Definitions and examples of each category are provided below. Please consult these definitions along with the MACIES Data Submission Rules and MACIES Industry Definitions before completing any data collection forms. Note that in order to maintain consistent reporting, discontinued category numbers may be removed without renumbering the remaining categories.

Please contact Scott Pepper or Helena Robinson with any questions.

General Guidance

- Process instrumentation generally carries some form of certification or approval for use in process environments, including (but not limited to) those listed below. Equipment lacking any of these certifications is unlikely to be suitable for process control applications.

- Smart devices incorporate microprocessors and support digital communication protocols such as HART, PROFIBUS PA/DP, or FOUNDATION Fieldbus. They also provide advanced diagnostic capabilities and may allow for signal compensation, conditioning, or self-calibration, all aimed at enhancing accuracy, repeatability, and reliability. Any product meeting the ‘smart’ definition should be classified as such, whether or not its smart features are actually utilised.

- Where high value mountings or process connections are sold with transmitters, these should be separated out to the contributor's best ability.

Product Category Definitions

(Please click the category title to open each of the definitions below)

Pressure

1.1 - Transmitters

Transmitters which respond to a measured variable by means of a basic sensing element, and convert it to a standard transmission signal (e.g. 4 to 20 mA/0 to 20 mA, digital), which is a function of the measurement, and can be physically separate from the receiving instrument. The transmitter may be used to measure pressure directly or flow indirectly (transmitters used to measure level are included in 3.5).

- Pressure and Absolute Pressure

- Fixed span devices

examples

- Rangeable devices

- Smart

examples

- Non-smart

examples

- Smart

- Fixed span devices

- Differential Pressure

- Rangeable devices; non-smart & smart

Excluded are: Flanged versions for level measurement – See 3.5

examples

- Rangeable devices; non-smart & smart

- Multivariable Pressure

A dedicated transmitter that measures differential pressure and static pressure, and either incorporates or accommodates a process temperature measurement, enabling the calculation of mass flow.

examples

Temperature

2.1 - Head Mounted

Commonly referred to as “Hockey Pucks” due to their shape, head-mount temperature transmitters are small, disc-shaped devices often mounted within a connection head. The connection head is usually attached directly to the sensor, though it may be located remotely. Only self-contained head-mounted transmitters should be included in this category. An input device being an integral part of a control system should not be reported here.

Thermowells and ancillary equipment should not be included in these figures.

examples

2.2 - Field Mounted

Field-mount temperature transmitters are designed with a dual-compartment housing that prevents moisture, humidity, or other contaminants from entering the transmitter’s electronics. Only self-contained, field-mounted transmitters should be included in this category. An input device being an integral part of a control system is not to be reported here.

Thermowells and ancilliary equipment should not be included in these figures.

examples

2.3 - Panel or Rack Mounted

Panel-mount (also called rack-mount or rail-mount) temperature transmitters are designed to be mounted on DIN-rails located in non-harsh environments usually in or near control rooms. Only self-contained panel mounted transmitters are to be included. An input device being an integral part of a control system is not to be reported in this category.

Thermowells and ancilliary equipment should not be included in these figures.

examples

Level

3.1 - Ultrasonic Level Transmitters & Systems

A transmitter or combination of transducer and control unit utilising the time of flight of ultrasonic sound through the ullage space above a medium to determine the level of the medium. This time of flight is converted into an output signal proportional to level or contents.

Note: Transmitters or systems for open-channel flow applications are included in this category.

- Ultrasonic Level Transmitters – liquid and dry product

examples

Also includes: Open channel ultrasonics for flow

examples

3.2 - Microwave Level Transmitters (Radar)

- Non-contacting Radar Transmitters (excl. Inventory Tank Gauging)

A transmitter or combination of antenna and control unit utilising time of flight of microwave signals through the ullage space above a medium to determine the level of the medium. This signal is converted to an output signal proportional to level or contents. Excluded are Inventory Tank Gauging (ITG) transmitters.

examples

- Inventory Tank Gauging Radar Transmitters

A transmitter or combination of antenna and control unit for use specifically in Inventory Tank Gauging applications utilising time of flight of microwave signals through the ullage space above a medium to determine the level of the medium. This signal is converted an output signal proportional to level or contents.

examples

- Guided Wave Radar (GWR) and Time Domain Reflectometry Radar (TDR)

A transmitter utilising the change in dielectric constant between two media to reflect part or all of a microwave pulse transmitted along a guide wire or rod. The return journey time of the pulse is used in calculations by the transmitter to determine the level of a liquid or dry product medium, or the interface between two liquid media, and to give an output signal proportional to level or contents.

examples

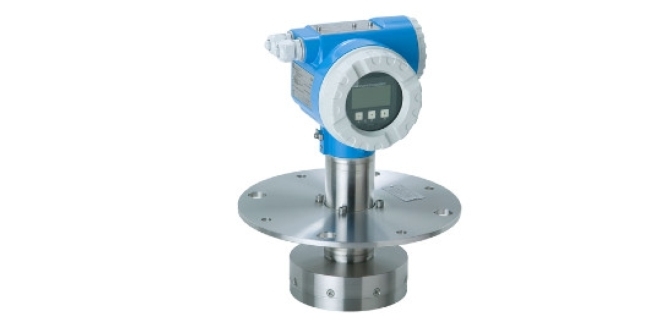

3.5 - Stand Alone Hydrostatic Sensors / Transducers or Pressure Transmitters for Measuring Level

A transmitter that has been modified or designed for mounting in or at the bottom of a tank of liquid and which contains a sensing element which measures the force exerted by the head of the liquid. The output of the device, digital, analogue or pneumatic, from either integral or remote signal conditioning is proportional to the head of liquid in the tank.

examples

Flow and Density Measurement

6.1 - Electromagnetic Flowmeters

Electromagnetic flow meters, or magmeters, are comprised of a transmitter and sensor that together measure flow. The magnetic flow meter’s sensor is placed inline and measures an induced voltage generated by the fluid as it flows through a pipe. The transmitter takes the voltage generated by the sensor, converts it into a flow measurement and transmits that flow measurement to a control system.

Sensor and transmitter, whether integrally or separately mounted, should be reported as one unit.

examples

6.2 - Coriolis Mass Flowmeters

A Coriolis flow meter contains a tube which is energized by a fixed vibration. When a fluid (gas or liquid) passes through this tube the mass flow momentum will cause a change in the tube vibration, the tube will twist resulting in a phase shift. This phase shift can be measured and a linear output derived proportional to flow.

Sensor and transmitter, whether integrally or separately mounted, should be reported as one unit.

examples

6.3 - Vortex Meters (excluding domestic)

Vortex meters utilise the Von Karman effect to measure fluid velocity. A dimensioned bluff/shedder bar is used to generate vortices, the frequency of these oscillating vortices is converted into fluid velocity and, along with the meter flow area, volumetric flow can be calculated.

Sensor and transmitter, whether integrally or separately mounted, should be reported as one unit.

examples

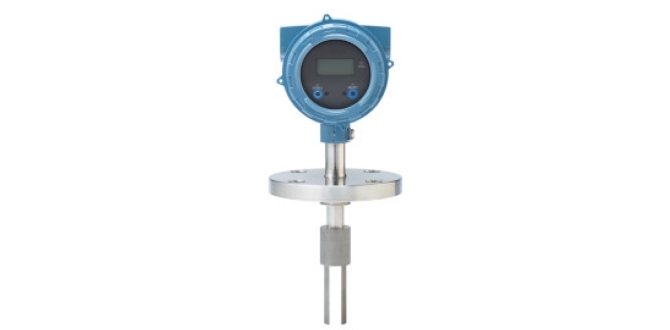

6.4 - Dedicated Density Measurement

Instrumentation technologies used to determine the density of a process fluid. Density measurements are often used to measure product quality, perform conversions between mass and volume or identify product interfaces. These measurements are needed anywhere that fluid value, quality or composition is important.

- Dedicated Density Measurement - Liquid

Density meters used for measuring density of liquids only. Includes all density measurement techniques including vibration, nucleonic and microwave.

examples

- Dedicated Density Measurement - Gas

Density meters used for measuring density of gases only. Includes all density measurement techniques including vibration, nucleonic and microwave. Specific gravity meters should be included here

examples

6.6 - Variable Area

Variable area flow meters are realatively simple devices that operate at a relatively constant pressure drop and measure the flow of liquids, gases, and steam. The position of their float, piston or vane is changed as the increasing flow rate opens a larger flow area to pass the flowing fluid. The position of the float, piston or vane provides an indication of flow rate. Design variations include the rotameter, orifice/rotameter combination, open-channel variable gate, tapered plug, and vane or piston designs.

Variable area flow meters provide a visual indication of flow and may also incorporate a transmitter to provide an analogue or digital signal output.

Category 6.6 includes all of the following:

- Variable Area - Metal

- Without transmitters

examples

- With transmitters

examples

- Without transmitters

- Variable Area - Glass

examples

6.7 - Ultrasonic

Ultrasonic flowmeters utilise sound waves to determine the velocity of a fluid flowing in a pipe and use this to calculate the flow rate. Included are transit time (or time of flight) and Doppler ultrasonic flow meters.

- Closed pipe

- Utilising wetted transducers mounted in a spoolpiece

examples

- Non-invasive: utilising clamp-on transducers

- Liquid

examples

- Gas

examples

- Liquid

- Utilising wetted transducers mounted in a spoolpiece

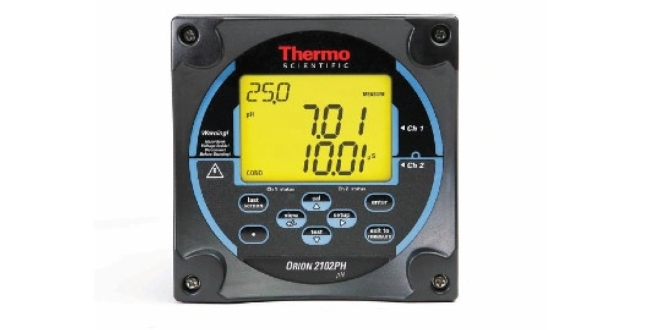

Analytical Instruments - Liquid

Note: For systems comprising both a sensor and a transmitter, contributors should separate these components to the best of their ability, to prevent high-value systems from skewing figures in either category. Similarly, where ancillary equipment such as sampling systems, retractable/high-value process connectors, or mounting systems is included, these should also be separated to avoid distorting figures in either category.

Analytical Instruments - Gas

9G a - Continuous Gas Analysis

Please ensure the definitions for categories 9G b, 9G c, and 9G d are reviewed before compiling any figures, as differences in terminology and categorisation may exist across various organisations in the industry. Submissions must align with the definitions outlined below to the best of the participant’s ability.

Continuous Gas Analysis refers to instrumentation that continuously measures specific gases in a process stream to provide real-time data for process control, environmental compliance, and safety. Products in this category may be viewed as single-species analysis ‘modules’ that can be combined to produce multi-species outputs. The following measurement technologies should be included in this category:

- IR Photometer

- UV Photometer

- Paramagnetic

- Thermal Conductivity

- FID

- Zirconia (excluding combustion O₂)

- Electrochemical

- Plasma

- Chemiluminescence

- Mercury (Hg)

9G b - Gas Chromatography

Please ensure the definitions for categories 9G a, 9G c, and 9G d are reviewed before compiling any figures, as differences in terminology and categorisation may exist across various organisations in the industry. Submissions must align with the definitions outlined below to the best of the participant’s ability.

Gas Chromatography (GC) refers to process instruments that separate and analyses gaseous mixtures in real or near-real time, enabling precise measurement of component concentrations for process control, quality assurance, and compliance. The following types of GC should be included in this category:

- Natural Gas GC

- Process Gas GC

- Speciality GC (ppm, ppb)*

* Note that for the MACIES 2025 collection, data on highly specialised GC systems (e.g. for the semiconductor industry) measuring trace-level concentrations will be included. However, if these systems differ too greatly in specifications or competitive environments compared to process or natural gas GCs—making it difficult to draw meaningful insights—their data may be withheld from general display. GAMBICA will also ensure any speciality GC submissions do not appear as outliers in the dataset, and will conduct a detailed review and discussion with participants before sharing any aggregated data with others.

examples

9G c - Spectrometry

Please ensure the definitions for categories 9G a, 9G b, and 9G d are reviewed before compiling any figures, as differences in terminology and categorisation may exist across various organisations in the industry. Submissions must align with the definitions outlined below to the best of the participant’s ability.

Spectrometry refers to process instrumentation that uses advanced optical measurement techniques to analyse process gases or liquids for composition, concentration, or other key parameters in real time. The following measurement technologies should be included in this category:

- Laser-based systems

- Fourier Transform Infrared (FTIR)

- Tunable Diode Laser Absorption Spectroscopy/Quantum Cascade Laser (TDLAS/QCL)

examples

9G d - Combustion Gas Analyser (O2)

Please ensure the definitions for categories 9G a, 9G b, and 9G c are reviewed before compiling any figures, as differences in terminology and categorisation may exist across various organisations in the industry. Submissions must align with the definitions outlined below to the best of the participant’s ability.

Combustion Gas Analysis (O₂) refers to instrumentation designed to measure oxygen concentration in combustion processes for efficiency, control, and safety. This category includes Zirconia devices specifically intended for combustion O₂ measurement

examples

Control Systems

10.1 - Distributed Control Systems - Hardware

All physical components forming a distributed control infrastructure - such as I/O controllers, control room cabinets, power supplies, operator workstations, and network switches.

Value only to be collected.

10.2 Distributed Control Systems - Software

All software packages supplied as part of a control system. This includes fundamental system software, engineering and configuration tools, human-machine interfaces (HMI), alarm management, data historians, cybersecurity solutions, and other applications that enable real-time monitoring, control, and optimisation within distributed control infrastructures.

Value only to be collected.

10.3 - Distributed Control Systems - Project Services

Covers services related to the design, configuration, and implementation of distributed control systems. This includes engineering, system configuration, and project management services to ensure successful deployment and integration of DCS solutions.

Value only to be collected.

10.4 - Distributed Control Systems - Operations Services

Encompasses services that support the ongoing maintenance, optimisation, and operational reliability of distributed control systems. This includes maintenance services, operational support, troubleshooting, and performance enhancements to sustain system efficiency and uptime.

Value only to be collected.

Recorders

11.5 - Parerless Recorders

Devices designed to electronically record and store measurement signals, such as electrical, temperature, and other process variables. This category includes data recorders capable of capturing both continuous and batch data in a secure digital format. It also covers recorders with or without integrated control or alarm features.

Positioners

15 - Control Valve Positioners - Smart

Devices that accurately control the position of a control valve and perform auto-calibration. In addition to positioning, smart positioners can communicate with a DCS, providing data such as valve position, pressure, diagnostic information, and fault status.

Wireless Adapters & Infrastructure

16.1 - Wireless Adapters (stand alone)

16.2 - Wireless Gateways and Repeaters

Infrastructure required to enable wireless instruments to connect to an industrial control system. This includes wireless gateways of all capacities and wireless signal repeaters. These devices facilitate reliable communication between wireless field devices and control systems.

Instrument Services

19 - Instrument Services

To include revenue from process instrumentation services (excluding DCS/Systems services), including:

- Installation & Commissioning

- Calibration

- Maintainence & Repair (excl. parts)

- Design and testing services

- Training